When we look at various mechanical components and fasteners used in industries worldwide, one product stands out due to its precise specifications and critical role in ensuring smooth functionality: the GISO 8735 – 10X26 – A-C1. This cylindrical pin, specified by the ISO 8735 standard, offers both versatility and strength, making it a key component in a wide range of applications. If you’ve ever wondered about the specific features, uses, and importance of the GISO 8735 – 10X26 – A-C1, this article will provide you with a detailed and comprehensive overview.

What Is the GISO 8735 – 10X26 – A-C1?

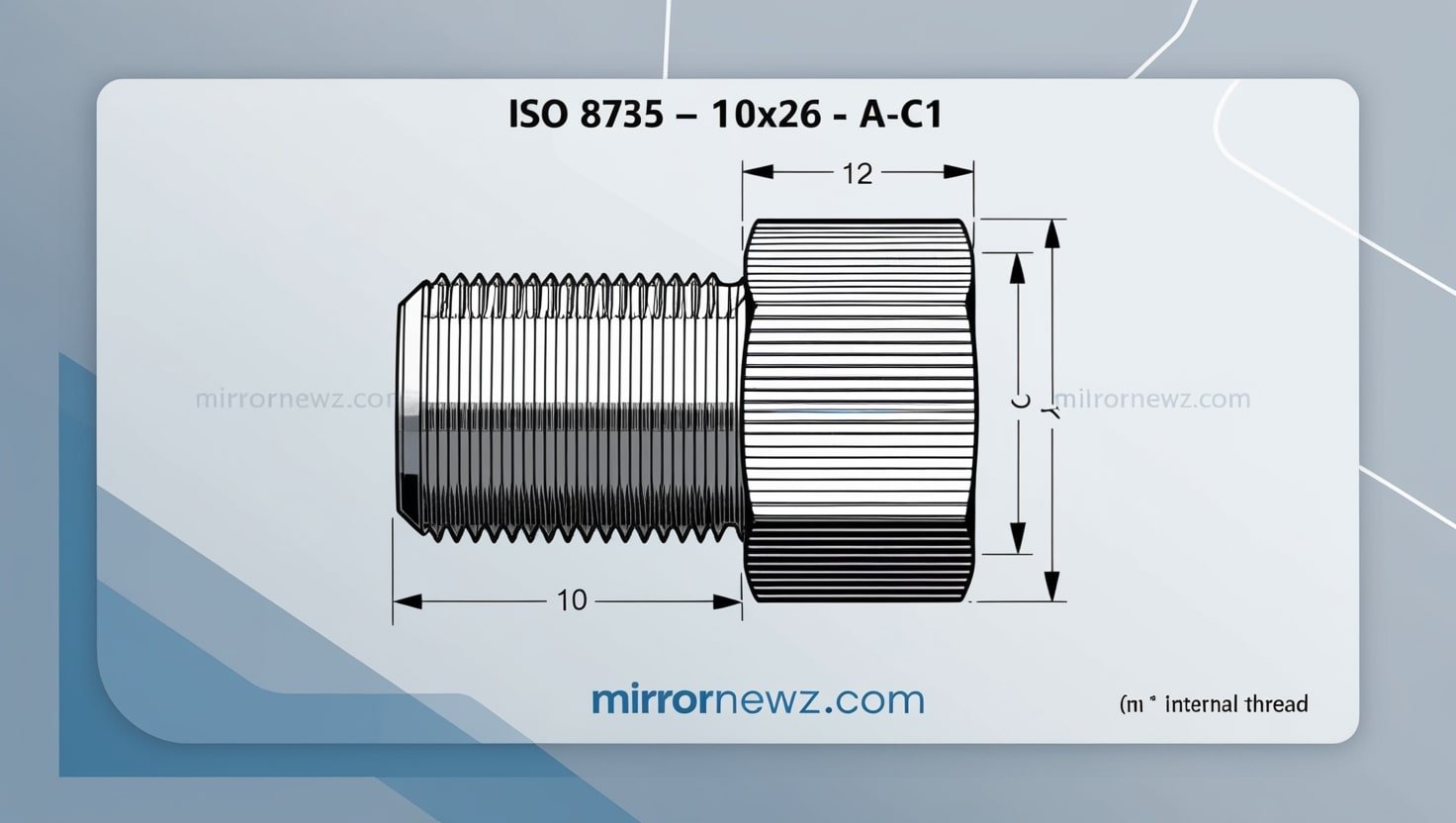

The GISO 8735 – 10X26 – A-C1 is a cylindrical pin that has been designed with both precision and reliability in mind. Following the ISO 8735 standard, it features an internal thread and is made from C1 grade stainless steel, which ensures durability and resistance to corrosion. The GISO 8735 – 10X26 – A-C1 has a nominal diameter of 10mm and a length of 26mm, which makes it perfectly suited for applications where compact and secure fastening is essential.

The pin’s “Type A” designation indicates that it is fully hardened, a key characteristic that significantly improves its strength and wear resistance. The combination of these elements makes the GISO 8735 – 10X26 – A-C1 a valuable component in industries that require reliability, strength, and long-term performance from their mechanical fasteners and connectors.

The Importance of the ISO 8735 Standard

Before diving into the detailed specifications of the GISO 8735 – 10X26 – A-C1, it’s important to understand the significance of the ISO 8735 standard itself. This international standard specifies the requirements for cylindrical pins, like the GISO 8735 – 10X26 – A-C1, with particular emphasis on their dimensions, materials, and design.

The ISO 8735 standard ensures that the pin you use for your mechanical applications is both reliable and capable of meeting the demands placed upon it. By adhering to this global standard, manufacturers can produce components like the GISO 8735 – 10X26 – A-C1 that meet the necessary performance and safety requirements. Whether you’re working in automotive, aerospace, or heavy machinery industries, adhering to ISO standards ensures that each part functions seamlessly with other components, leading to more efficient systems and reduced operational risks.

The Composition of GISO 8735 – 10X26 – A-C1: Material and Durability

One of the most crucial aspects of the GISO 8735 – 10X26 – A-C1 is its material composition. This cylindrical pin is made from C1 grade stainless steel, a high-quality, corrosion-resistant alloy that excels in demanding environments. Stainless steel is known for its ability to withstand harsh conditions, such as exposure to moisture, chemicals, and extreme temperatures.

The use of C1 grade stainless steel in the GISO 8735 – 10X26 – A-C1 ensures that it has excellent mechanical properties, including high tensile strength and resistance to deformation. This makes it an ideal choice for applications in industries like automotive, construction, and machinery, where components are subjected to substantial loads and stresses.

Moreover, the fully hardened design of the GISO 8735 – 10X26 – A-C1 significantly enhances its durability, ensuring that it can endure wear and tear over extended periods of use without compromising its structural integrity. The hardening process is crucial for ensuring the longevity and reliability of the cylindrical pin, especially in high-stress environments.

Dimensions and Design: How GISO 8735 – 10X26 – A-C1 Fits Into Various Applications

The GISO 8735 – 10X26 – A-C1 is designed with a nominal diameter of 10mm and a length of 26mm, making it compact yet highly effective. These specific dimensions allow the pin to fit seamlessly into a wide range of mechanical systems and applications where precise dimensions and a secure fit are required.

The internal thread of the GISO 8735 – 10X26 – A-C1 allows it to be used as part of fastening systems that require a threaded connection. This feature makes the pin an essential component in systems where you need to connect or secure parts with a high degree of stability. For example, in automotive and aerospace industries, the GISO 8735 – 10X26 – A-C1 might be used to secure parts within engines, transmissions, or other critical systems where vibration and movement could otherwise cause loose connections.

Additionally, the Type A designation of the GISO 8735 – 10X26 – A-C1 means it is fully hardened, which not only contributes to the pin’s strength but also makes it ideal for use in applications where resistance to fatigue and wear is critical.

Applications of the GISO 8735 – 10X26 – A-C1

The GISO 8735 – 10X26 – A-C1 cylindrical pin is used in a variety of industries, owing to its versatile design and durable material properties. One of the most common uses is in machinery, where it serves as a fastener to secure components in place. In automotive applications, it might be used in the assembly of engine parts, drive shafts, and other mechanical systems that require precise alignment and secure fastening. The GISO 8735 – 10X26 – A-C1 is particularly useful in parts that experience high mechanical stress and need a reliable fastening solution.

In the aerospace industry, this pin could be used in structural applications where strength, lightweight design, and corrosion resistance are crucial. The GISO 8735 – 10X26 – A-C1’s fully hardened design ensures that it can handle the high levels of stress and extreme temperatures that are common in aviation applications.

Another area where the GISO 8735 – 10X26 – A-C1 proves to be useful is in construction machinery. Heavy-duty equipment often requires robust and reliable fasteners to keep different parts securely in place, especially under fluctuating loads. The GISO 8735 – 10X26 – A-C1 is an excellent solution due to its strength and resistance to corrosion, ensuring that it remains functional in tough environments.

The Benefits of Choosing GISO 8735 – 10X26 – A-C1

Choosing the GISO 8735 – 10X26 – A-C1 comes with several significant benefits, which make it a preferred option for many industries. First and foremost, its C1 grade stainless steel construction offers superior corrosion resistance, ensuring that the pin will maintain its structural integrity even in harsh conditions. This is particularly important in industries like automotive, aerospace, and marine, where exposure to moisture, chemicals, or extreme temperatures is common.

Additionally, the fully hardened nature of the GISO 8735 – 10X26 – A-C1 ensures that it has excellent wear resistance. This means that even with continuous use, the cylindrical pin will retain its strength and functionality over time, making it an ideal choice for long-term applications.

The precision dimensions of the GISO 8735 – 10X26 – A-C1 also contribute to its overall effectiveness. Its nominal diameter of 10mm and length of 26mm are designed to fit perfectly into standard mechanical systems, allowing for a secure connection and reliable performance.

GISO 8735 – 10X26 – A-C1 in High-Performance Environments

In high-performance environments, where safety, reliability, and durability are paramount, the GISO 8735 – 10X26 – A-C1 excels. Its hardened design, coupled with its corrosion-resistant material, makes it a reliable choice for parts that need to perform under extreme conditions. Whether used in high-speed machinery, heavy-duty construction equipment, or aerospace systems, the GISO 8735 – 10X26 – A-C1 can withstand the demands placed upon it without compromising on performance.

For instance, in automotive racing, where every component must be engineered for maximum performance, the GISO 8735 – 10X26 – A-C1 can play a crucial role in ensuring the secure fastening of critical parts. The same applies to aerospace and aviation, where high-quality fasteners are essential for maintaining the safety and functionality of aircraft during flight.

Maintenance and Longevity of the GISO 8735 – 10X26 – A-C1

The longevity of the GISO 8735 – 10X26 – A-C1 can be ensured with proper maintenance. Despite its durability, regular inspections are important to confirm that the cylindrical pin has not experienced excessive wear or damage. Since the GISO 8735 – 10X26 – A-C1 is made of stainless steel, it requires minimal maintenance beyond occasional cleaning and lubrication, especially when used in high-stress environments.

Proper maintenance will help preserve the internal thread and prevent corrosion from affecting the performance of the GISO 8735 – 10X26 – A-C1. In applications where the cylindrical pin is exposed to moisture or chemicals, routine cleaning and inspections are recommended to maintain its effectiveness and longevity.

Conclusion

The GISO 8735 – 10X26 – A-C1 cylindrical pin is a critical component in many mechanical and industrial systems due to its precise specifications and reliable performance. With its C1 grade stainless steel construction, fully hardened design, and adherence to the ISO 8735 standard, the GISO 8735 – 10X26 – A-C1 is well-suited for use in high-performance environments that demand durability and strength.

From automotive to aerospace, construction machinery to industrial systems, the GISO 8735 – 10X26 – A-C1 provides a secure and reliable solution for fastening needs. Its superior corrosion resistance, wear resistance, and precision design make it a versatile and durable choice for various industries. By understanding the features and benefits of the GISO 8735 – 10X26 – A-C1, you can confidently choose it for your next project, ensuring the safety, reliability, and longevity of your mechanical systems.